Automatic coding systems for online printing on a wide range of surfaces such as corrugated boxes, paper bags, cement bags, textiles, asbestos sheets, cartons, and more are designed to seamlessly integrate with conveyor systems and taping machines. These advanced systems offer precise and registered coding of packaging information, ensuring exceptional print quality and efficiency.

Key features of this coding system include:

- Continuous Operation: The system is designed to operate continuously, accommodating the fast-paced environment of production lines.

- Spring-Loaded Marker: Equipped with a tension spring, the marker returns to its zero position after each stroke. This ensures consistent and accurate printing on the packaging materials.

- Re-inking Mechanism: The system is designed with an efficient re-inking mechanism located below the ink roller. This ensures that the ink roller is replenished with ink after every stroke, allowing for uninterrupted printing.

- High-Quality Printing: The system guarantees excellent print quality, ensuring that each impression is marked perfectly. This is crucial for legibility and branding.

- Pivoting Assembly: The entire assembly is pivoted under positive tension, enhancing stability and precision during the printing process.

- Interlocking Typeface: The typeface used in this system is designed with an interlocking arrangement. This not only ensures secure attachment to the roller during operation but also allows for easy removal and replacement for different applications.

- Excellent Print Quality: The entire assembly is pivoted under positive tension. Each impression is marked perfectly, Interlocking Typeface The interlocking arrangement of the typeface provides secure attachment to the roller whilst in use but also allows for the easy removal for different applications.

-

Versatile Mounting: The mounting arrangement for the AutoCoder is universal – it can be installed in almost any position or location within minutes. Easily adjusted to mark different sizes of cartons.

-

User-friendly: Print position can be changed while in use. Can be adjusted for random marking

APPLICATIONS

On-line marking on automatic case sealing machines, case erectors, powered/roller conveyers continuously moving paper, film, aluminium/ galvanised sheets and many other surfaces :

- Batch Number

- Date of Manufacture

- Expiry Date

- Name and address of Customer/Manufacturer

- Product Name/Code

- Shipping Instructions

- Packing Details

- Net Weight/Gross Weight

- Price

- Invoice Number

- Statutory Markings

- Logos / Brand names

PROCEDURE

Mounting

-

- Install base [1] in the chosen position for mounting

- Fix it exactly parallel to the coding surface with the help of two bolts

- Insert pivot [2] into the base gravity

- Position the pivot to the required height

- The arm should be towards the inside of the belt when you tighten with bolt [3]

Inserting the ink roller

Inserting the ink roller

-

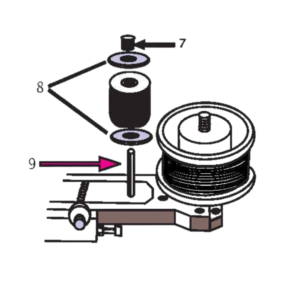

- Place the Inking roller assembly [8] on axel [9]

- Adjust the pressure from the upper part with knurled knobb [7]

Inserting & removing the drum

Inserting & removing the drum

-

- Insert the drum [5] in such a way that the cavity in its base engages with the spigot of the bearing

- [6] Fix it by its upper part giving the knob [4] a quarter turn to the right

- Reverse the process to remove it.

Adjusting marking & inking pressures

Adjusting marking & inking pressures

-

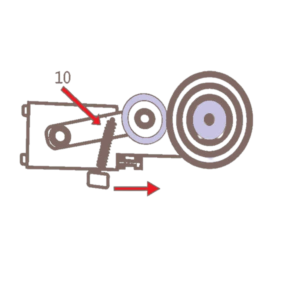

- Use the two lateral bolts [10] to adjust the marking pressure depending on the marking surface characteristics

- Use the knob [11] to regulate the pressure of the inking roller against the typeface

- This increases or decreases the amount of ink deposited per impression

- When used together, these adjustment ensure a consistently excellent print quality

Message position setting

Message position setting

-

- Hole [14] are provided on bottom of the print wheel [5]

- Eccentric cam [15] is provided with a pin [16]

- Starting point of the message can be adjusted by changing the position of the print wheel

- The print wheel can be adjusted upto 360 degree by inserting the pin into the appropriate hole

Changing Drum Position & Balance Adjustment

Changing Drum Position & Balance Adjustment

-

- Use holes [12] to position the drum as per required print position left or right

- Remember to readjust the lateral bolts [10] and the knob [11] to adjust the marking and inking roller pressure before use

- There is a spring connected to the bearing of the drum in the lower part of the support

- Change between the 3 position of fixing bolt [13] to brake the balance of the drum in its rotation

This advanced automatic coding system is a valuable addition to manufacturing and packaging processes, improving efficiency, accuracy, and overall product quality. Whether you’re in the corrugated box industry, paper bag production, cement bag manufacturing, textiles, asbestos sheet production, carton assembly, or other packaging applications, this system can be tailored to meet your specific needs

Reviews

There are no reviews yet.