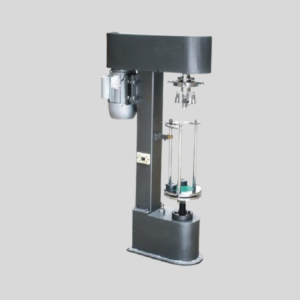

Introducing our Automatic Single-Head Rotary Capping Machine, meticulously engineered to redefine cap sealing efficiency within the 100mL to 1000mL range. This innovative equipment is your solution for achieving seamless and precise bottle closures, effortlessly.

Designed for versatility, this single-head rotary capper ensures that caps are tightened consistently, eliminating the guesswork from your production line. Its robust build and precision engineering guarantee dependable performance, even with high-strength caps.

The Automatic Single-Head Rotary Capping Machine offers a range of advanced features, including adjustable torque settings to accommodate various cap sizes and materials. This adaptability makes it an indispensable tool for industries ranging from pharmaceuticals to cosmetics, food, and beverages.

With its user-friendly interface, operating this capper is intuitive. The machine efficiently tightens each cap to the desired level and halts rotation, signaling readiness for the next bottle. This not only saves time but also maintains the integrity of your products.

In addition to its precision, this machine is built for durability, ensuring longevity and reliability in your production processes. Its user-friendly design and low maintenance needs make it an asset to any operation.

Experience the future of cap sealing with our Automatic Single-Head Rotary Capping Machine. Whether you’re working with 100mL or 1000mL bottles, this equipment delivers consistent, efficient, and dependable results, streamlining your production while maintaining quality.

Automatic Cap Sealing machine is design to cap 40 to 55 bottles per min. The machine is fully automatic and is robust construction, complete with Vibratory for cap feeding and slat conveyor. A Star Plate of suitable size transfers the incoming bottle with caps and feed it under the Sealing Head. The synchronized movement of the bottles and the sealing mechanism provides perfect sealing. The SS Slat conveyor shall be provided with guide rail, which can be adjusted for different size of bottles. A Star wheel with bottle guide is needed for different dia. .For Smooth Running of Star Wheel we use Induxture.

The drive mechanism shall be arranged at the bottom in an enclosed cabinet. The control penal box shall be provided in front for easy operation. All SS parts shall be met finish and MS parts duly painted and cladded with SS Sheet. For different types of bottles and caps, change parts required which will be charged extra.

Reviews

There are no reviews yet.